Frontline thinking, achieving real results

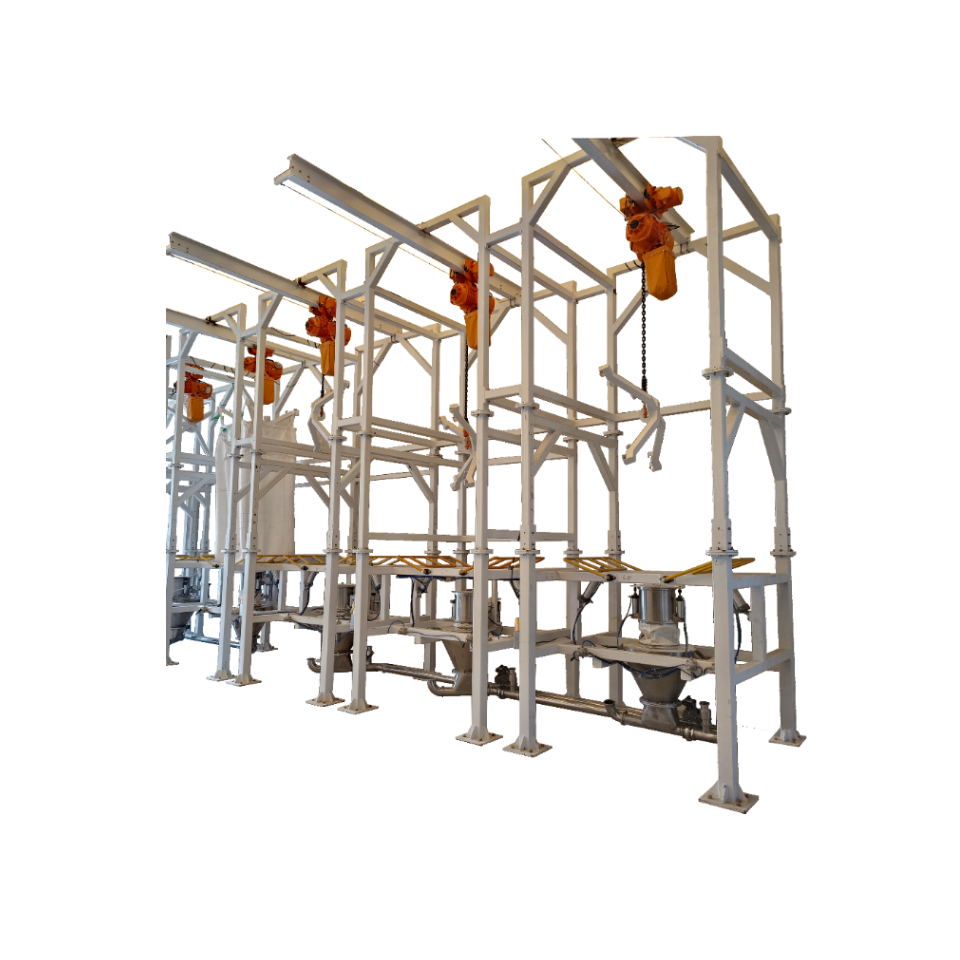

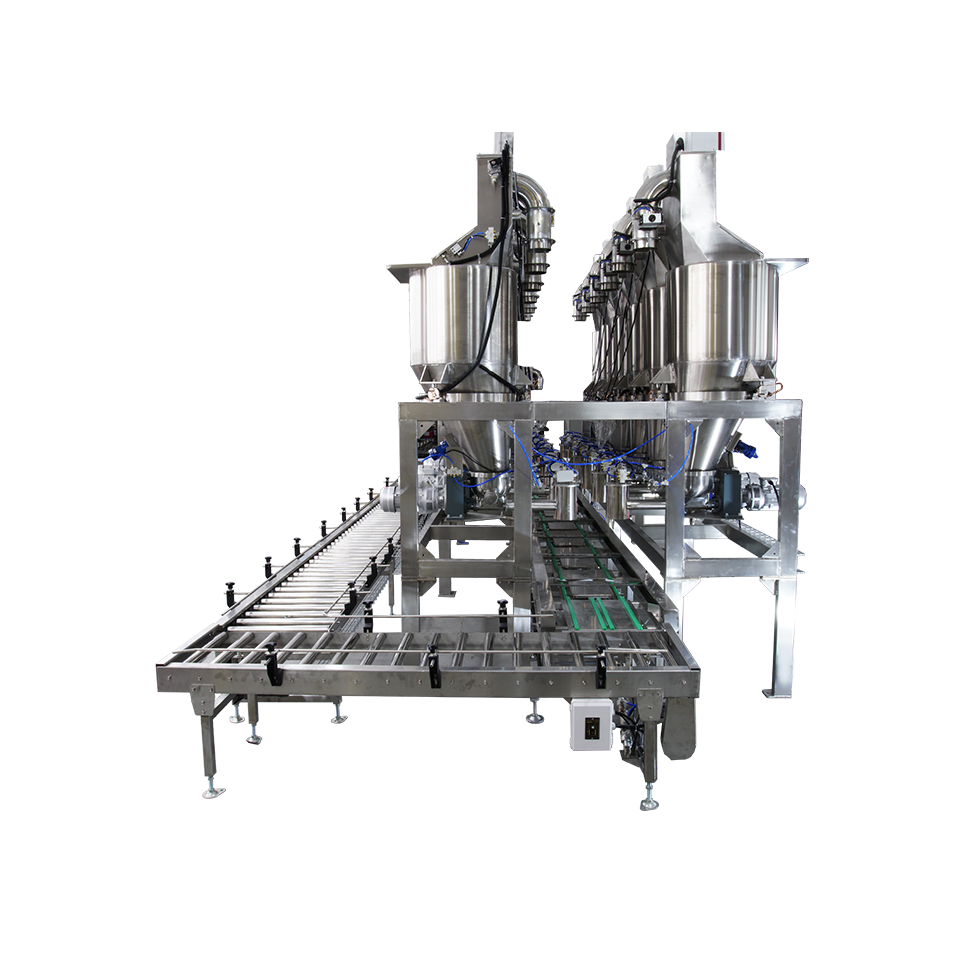

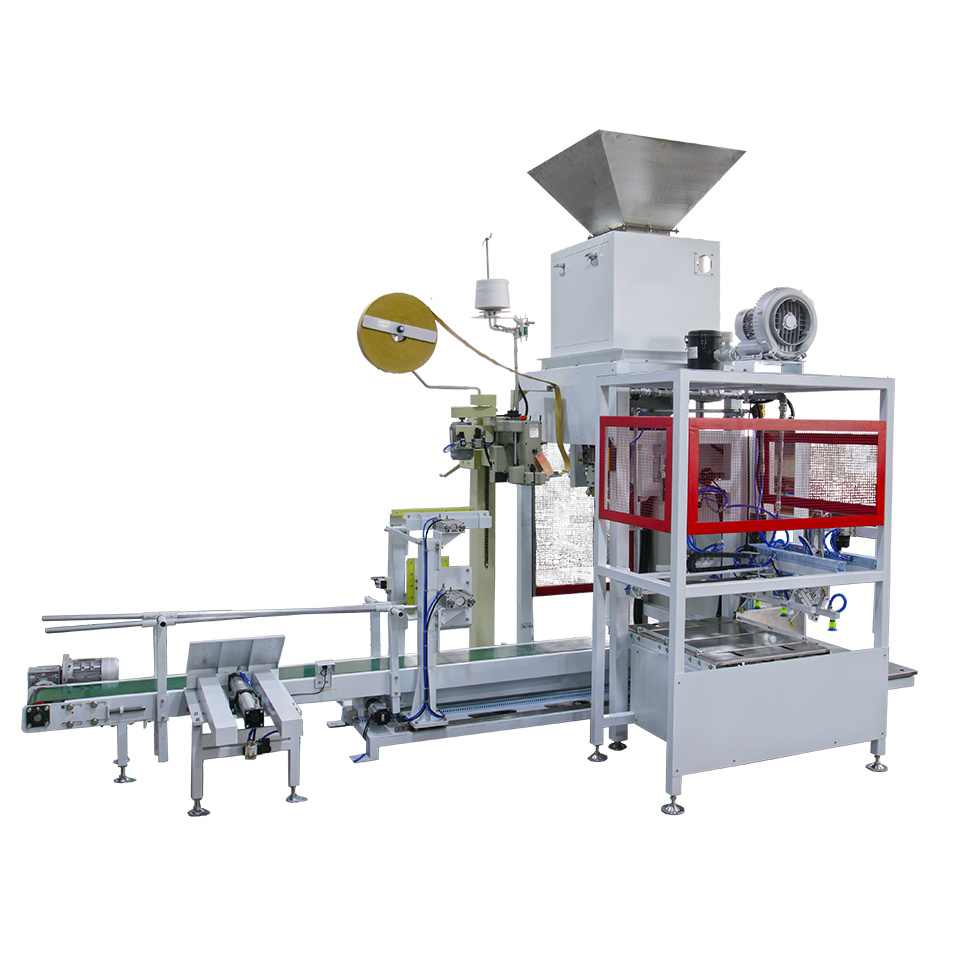

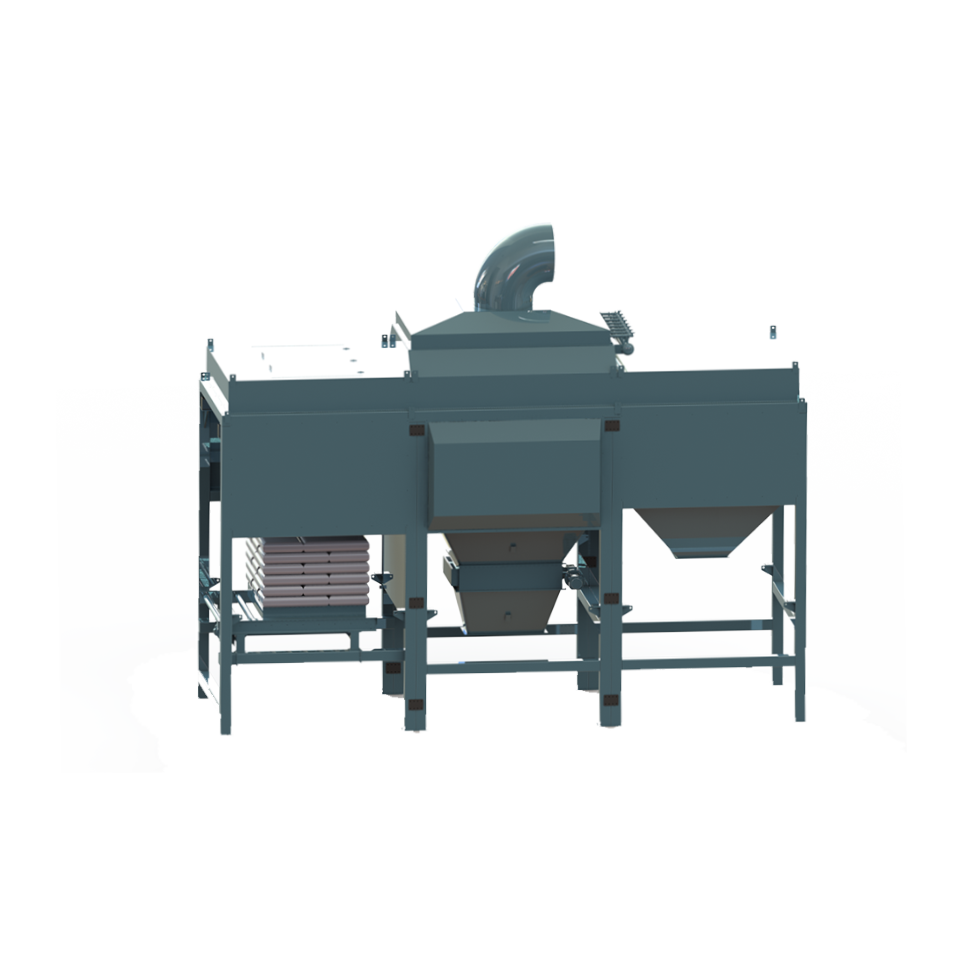

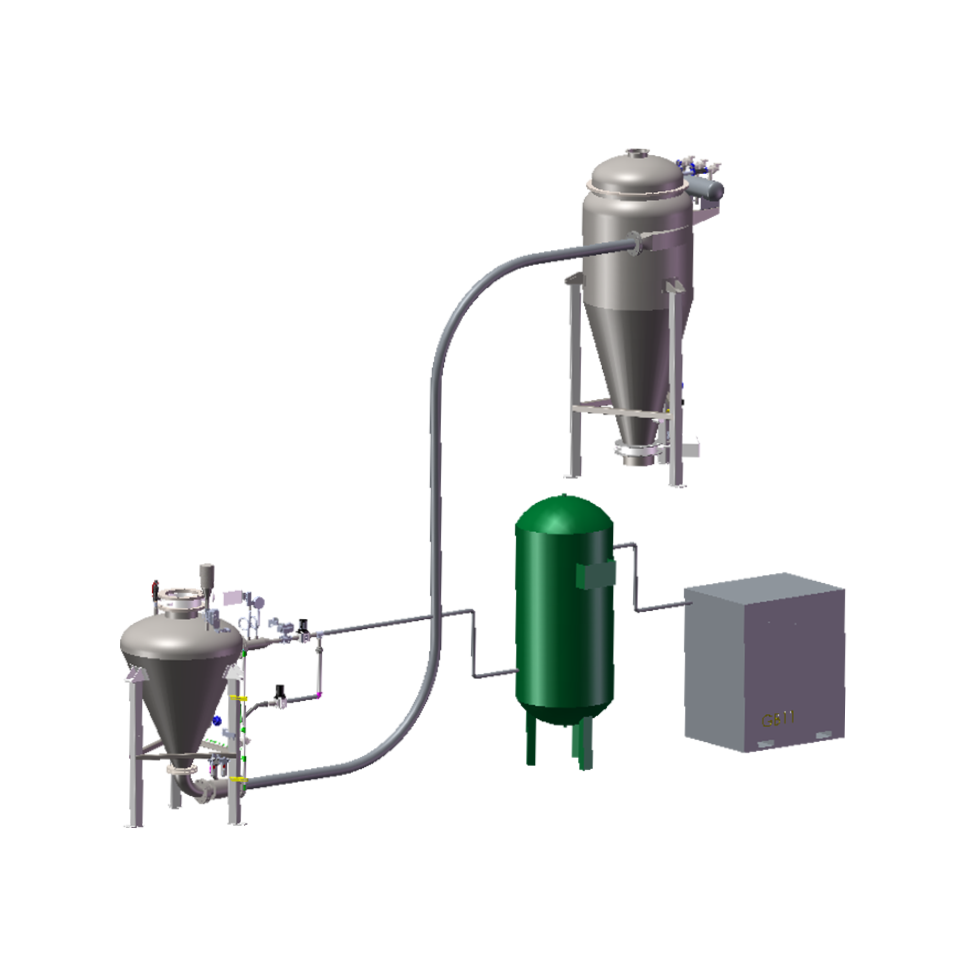

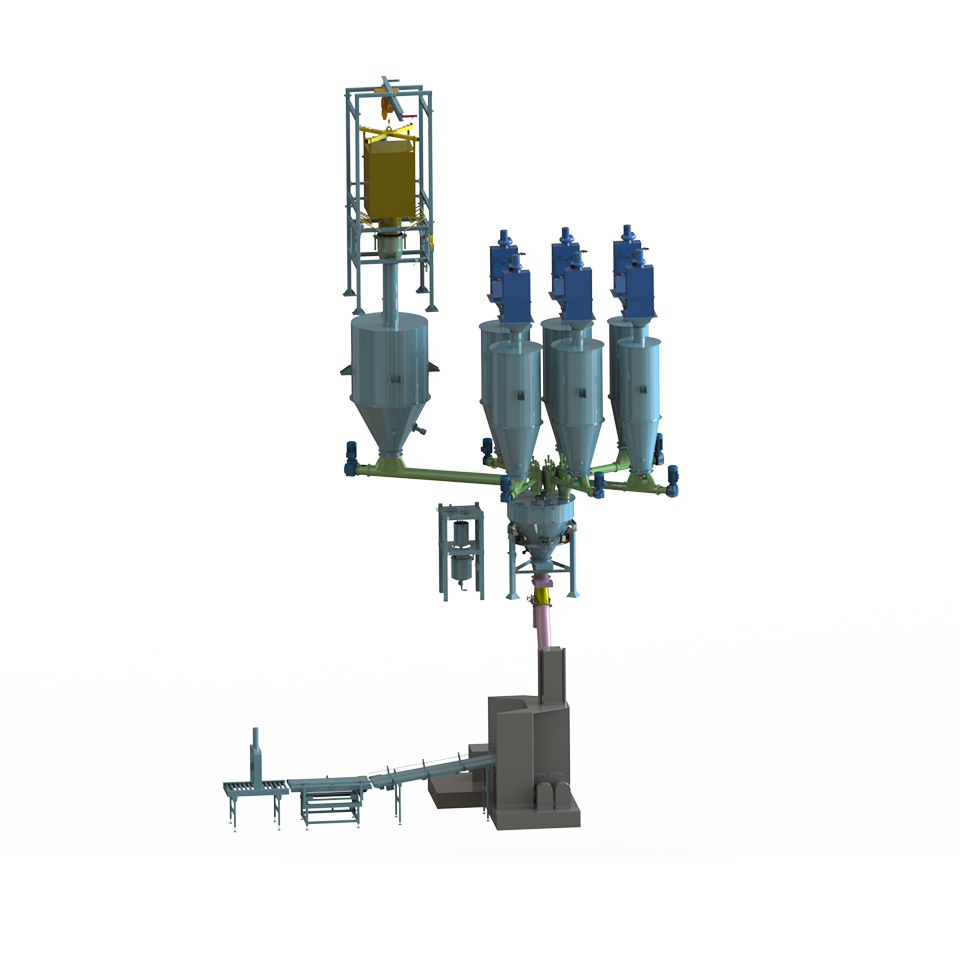

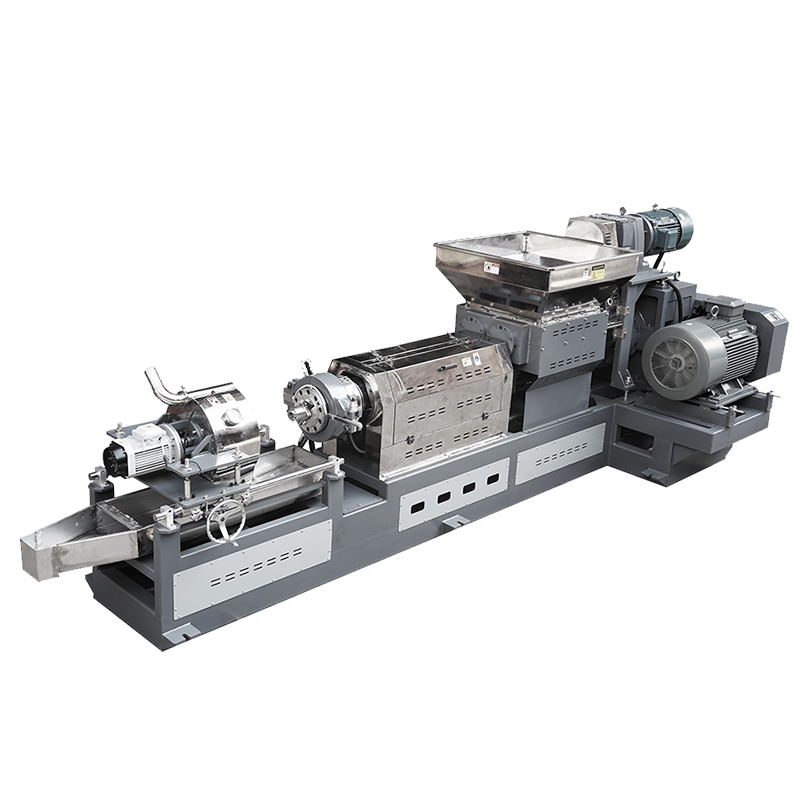

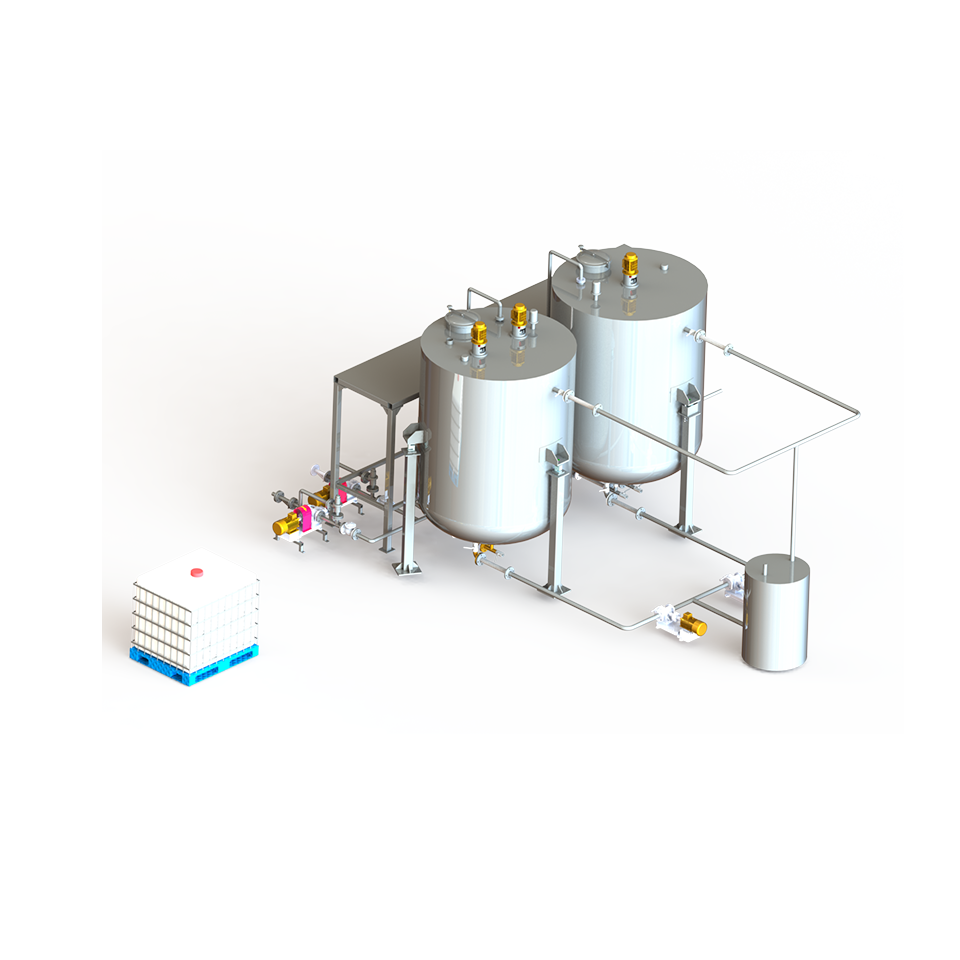

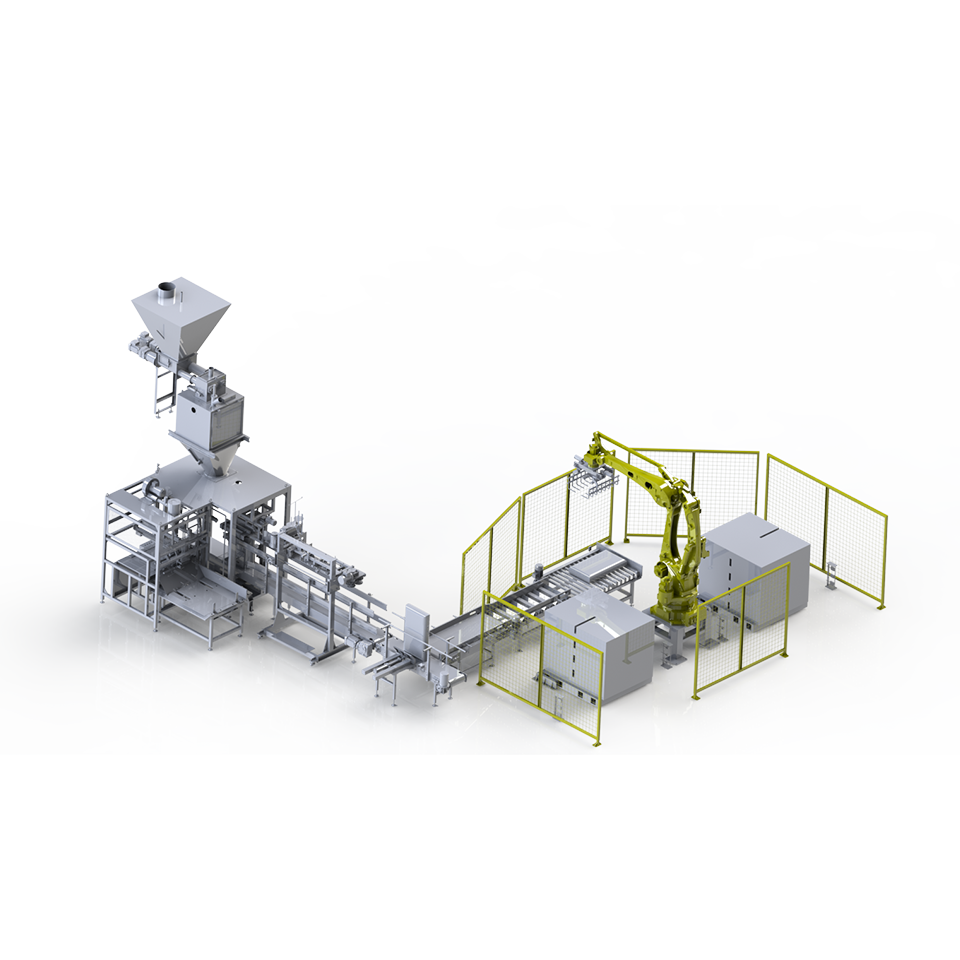

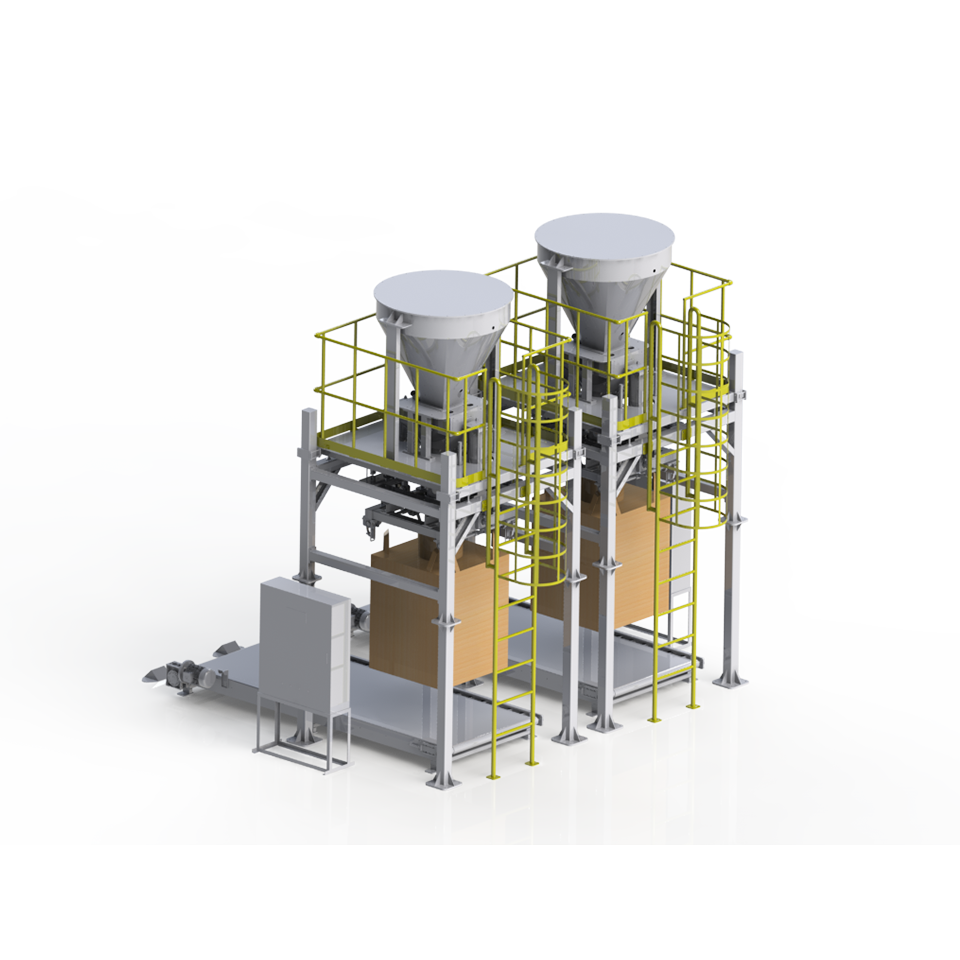

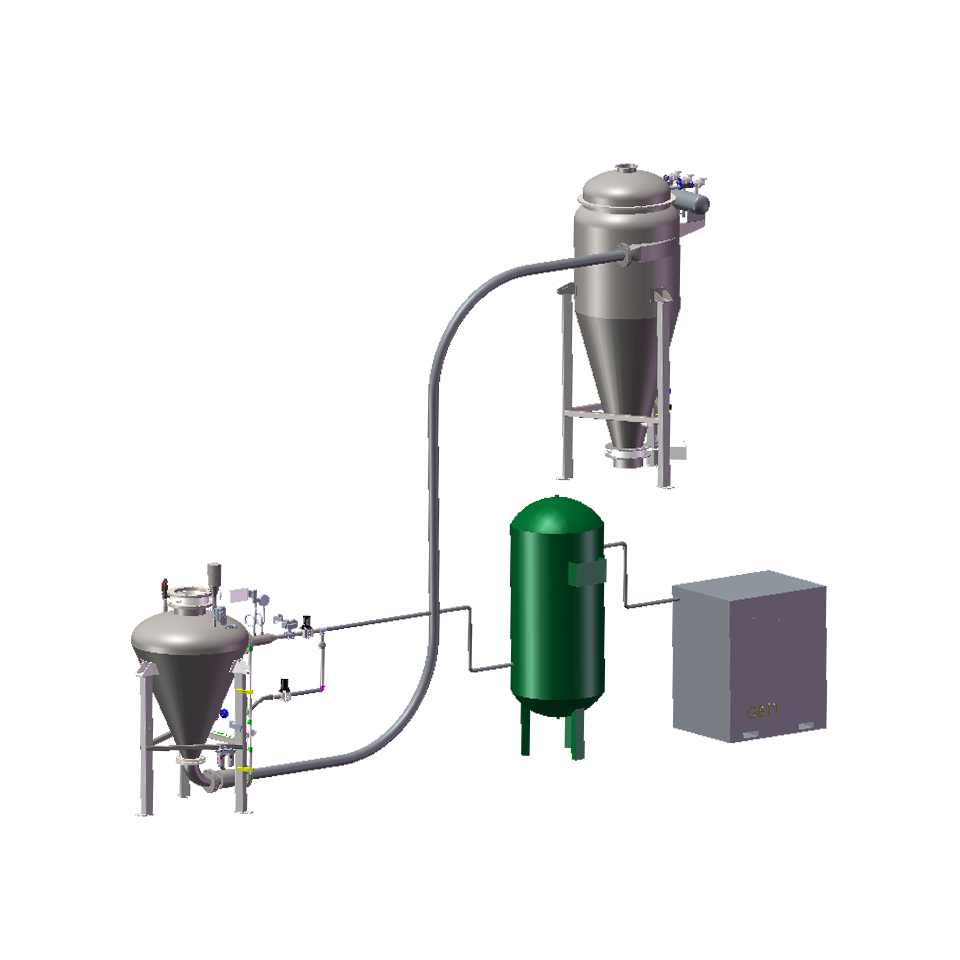

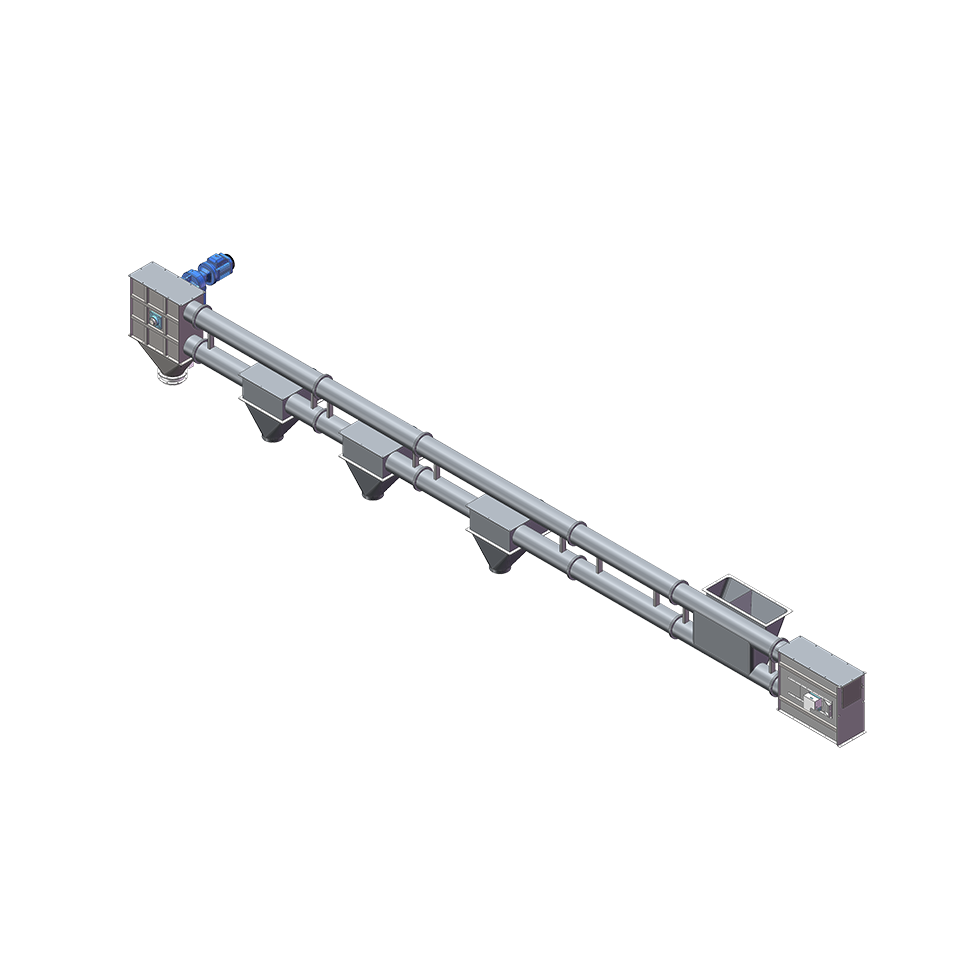

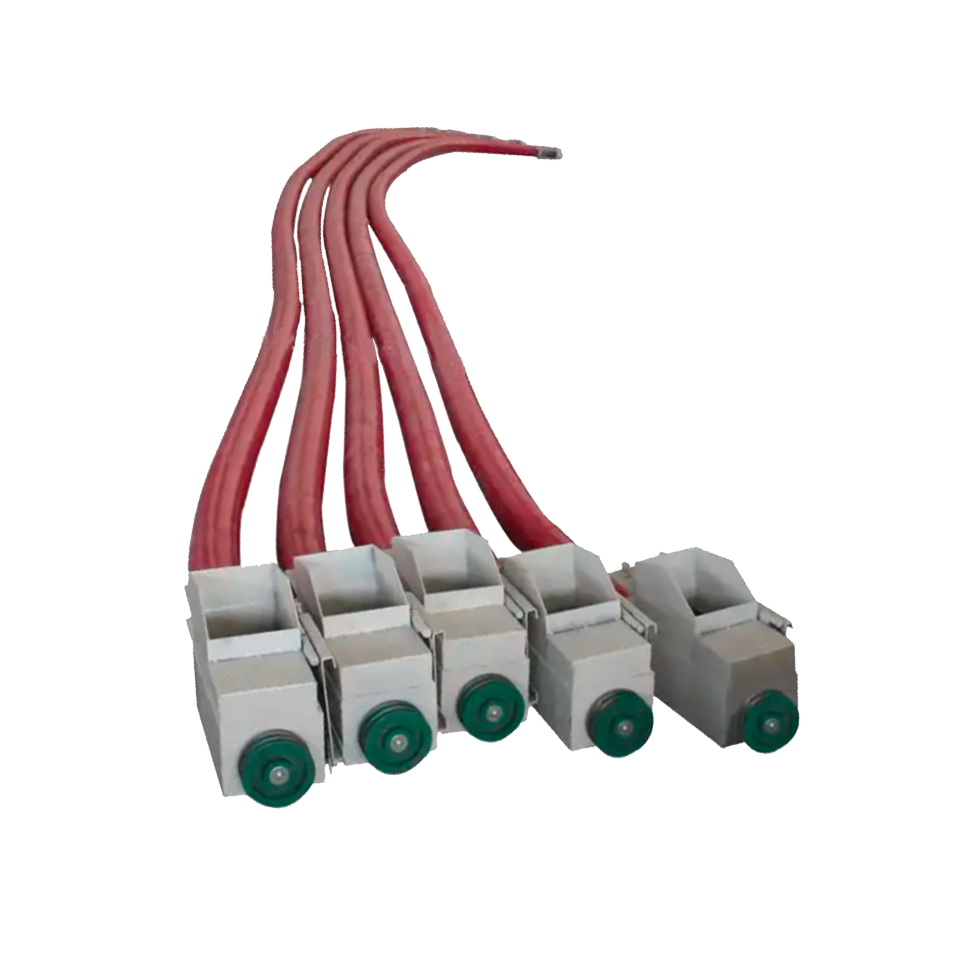

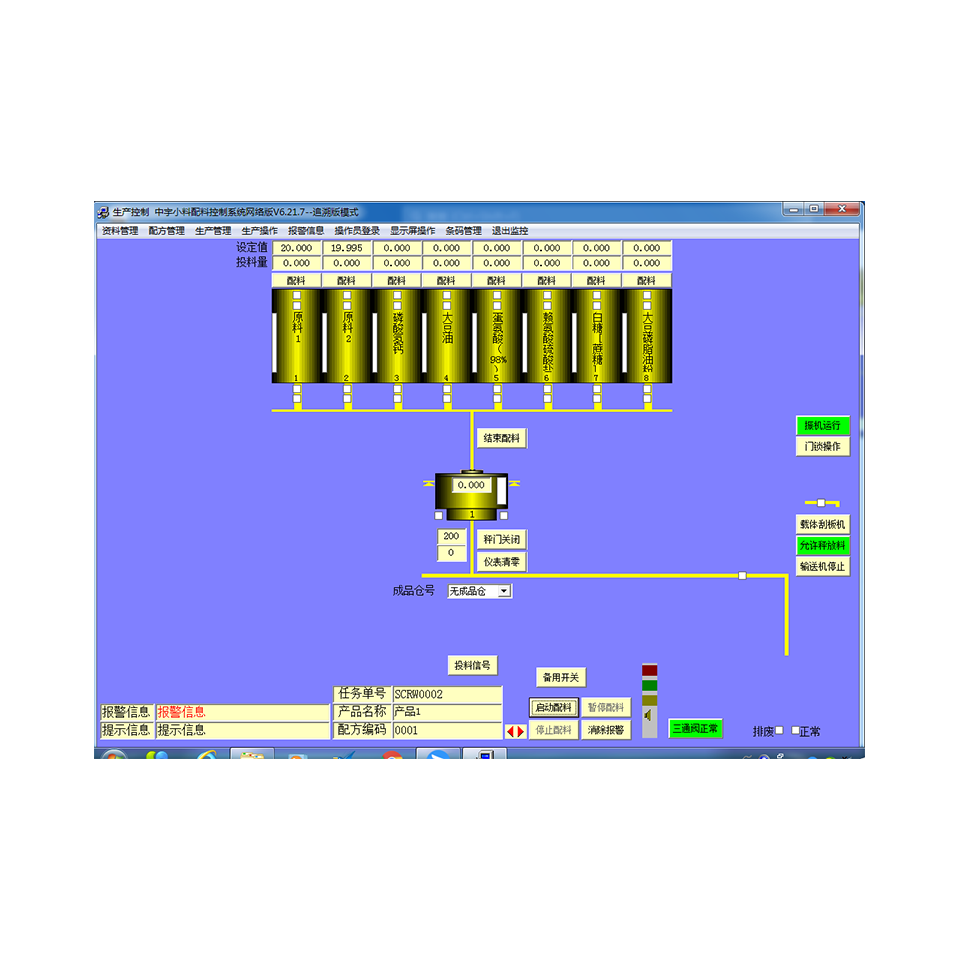

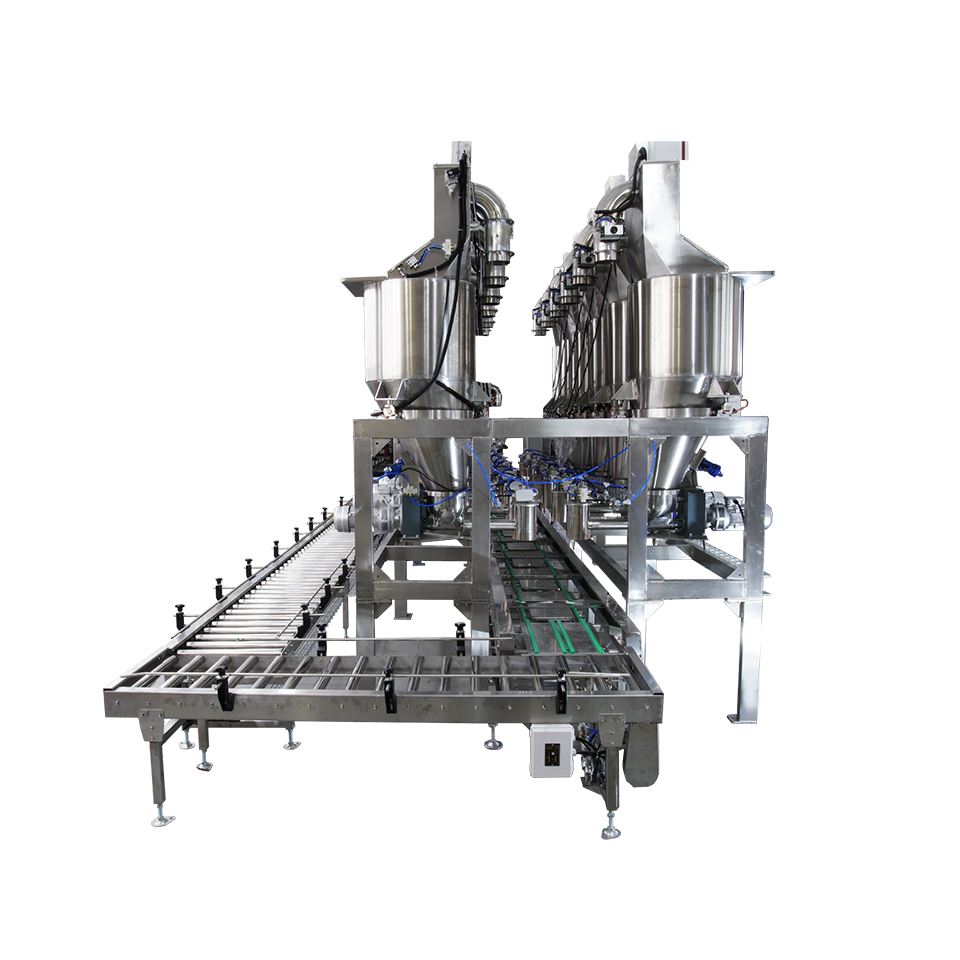

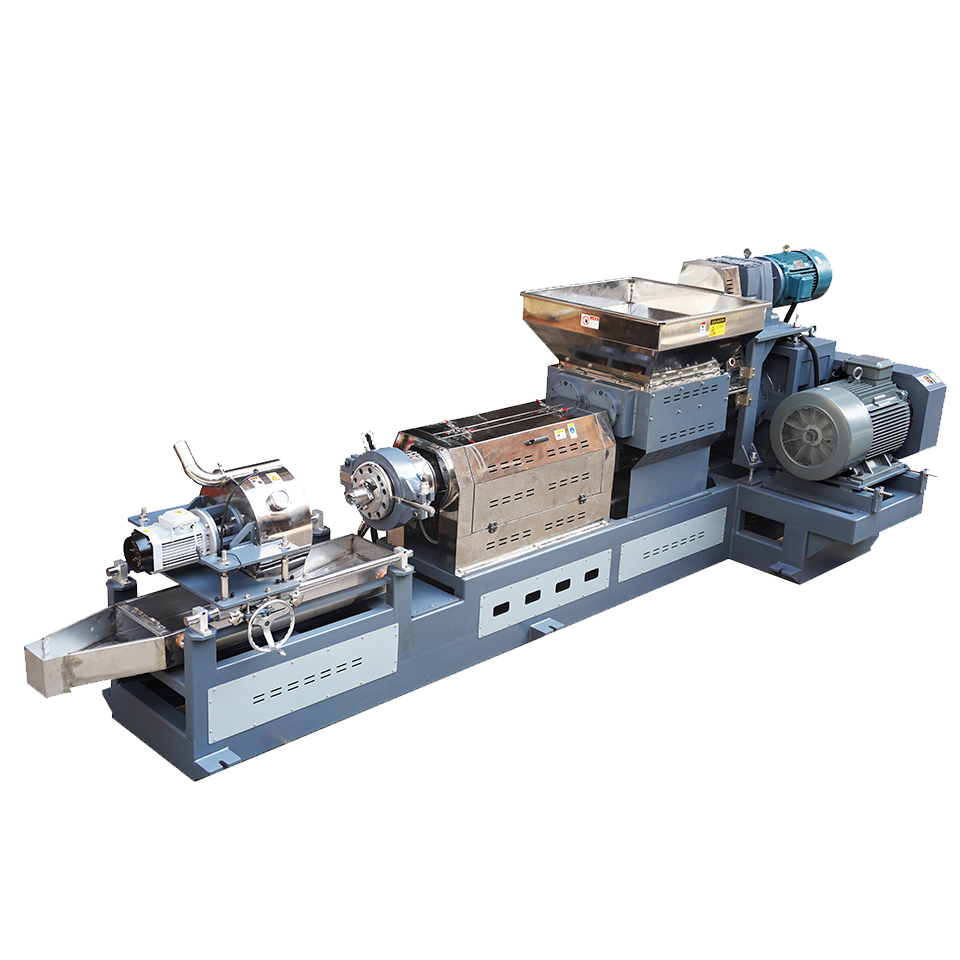

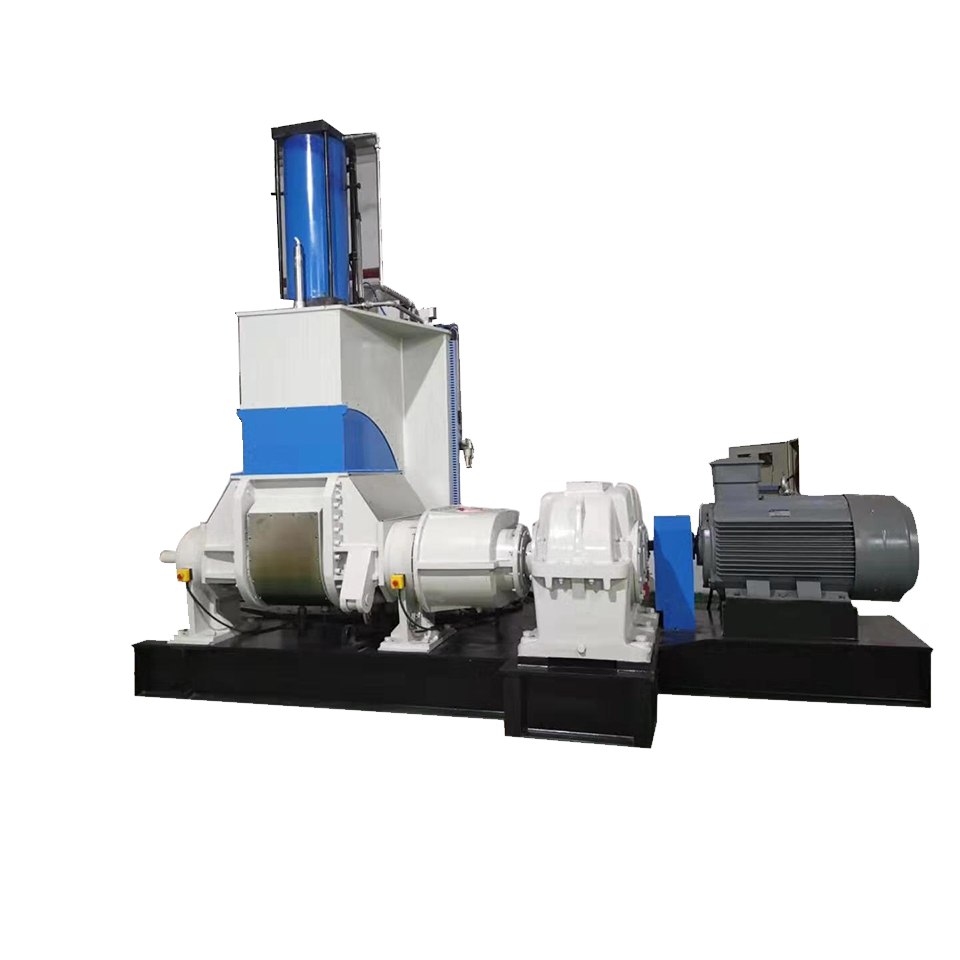

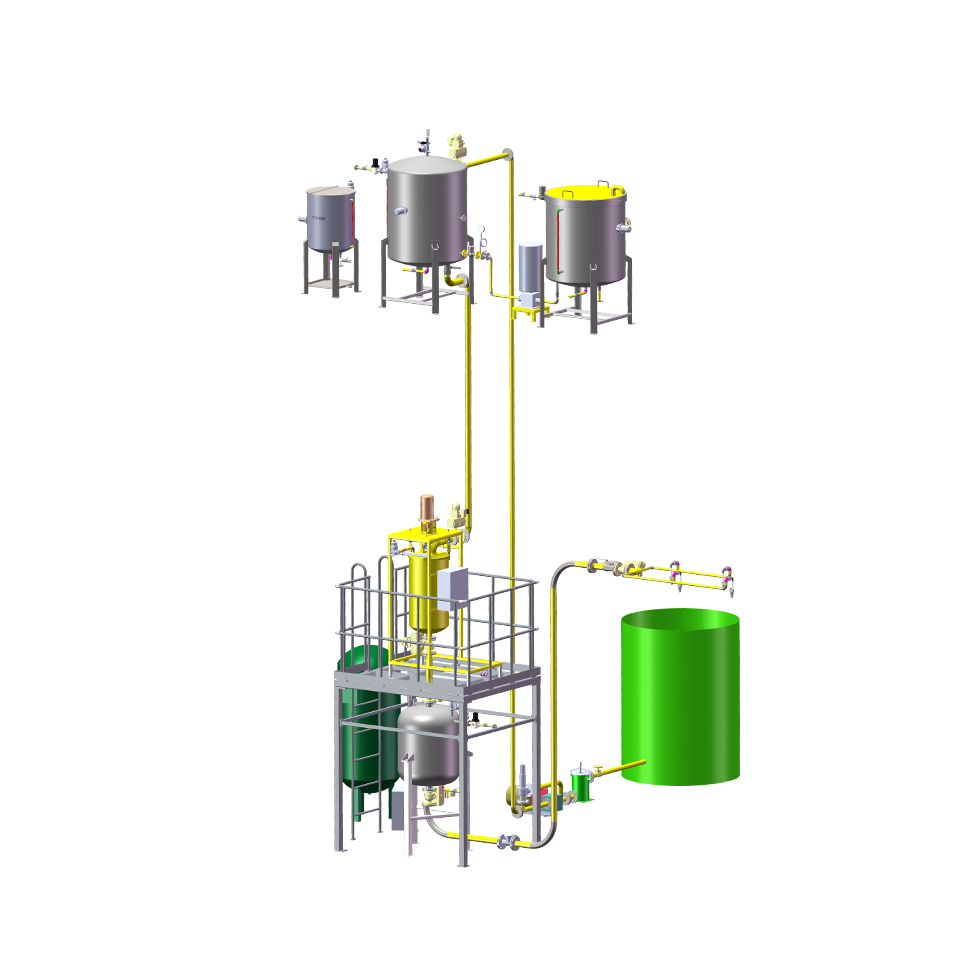

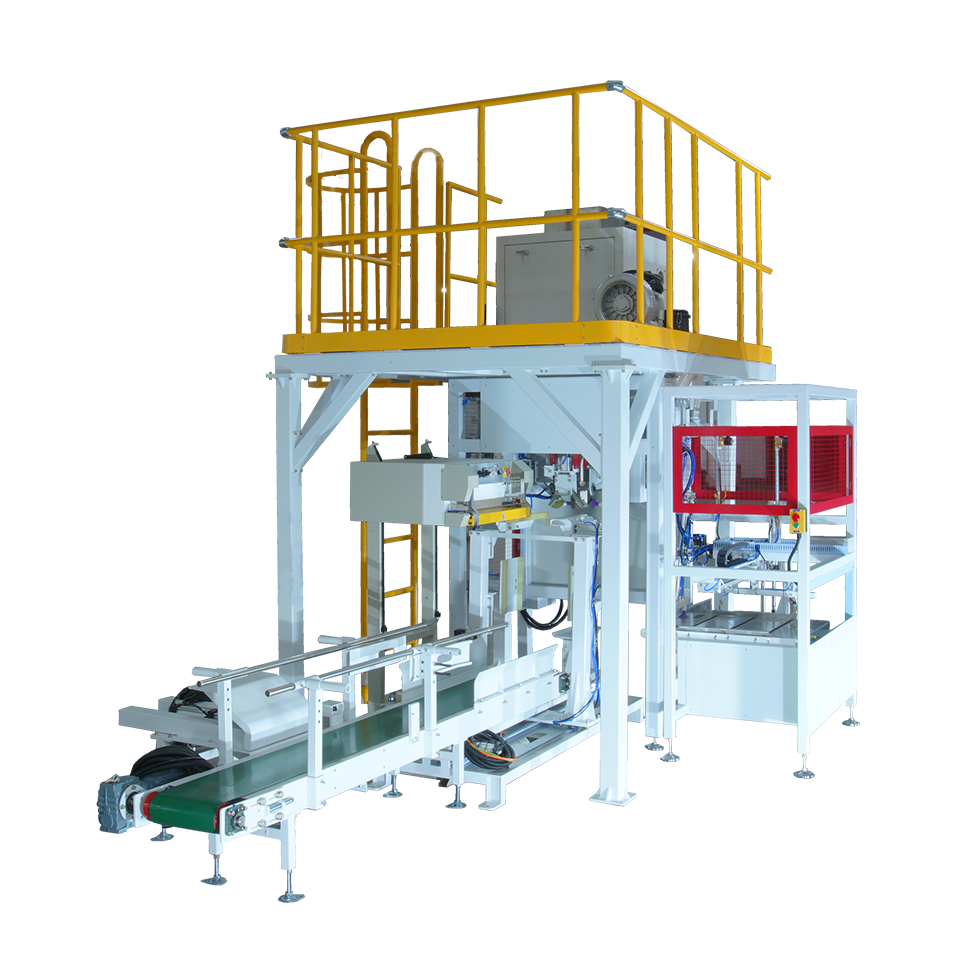

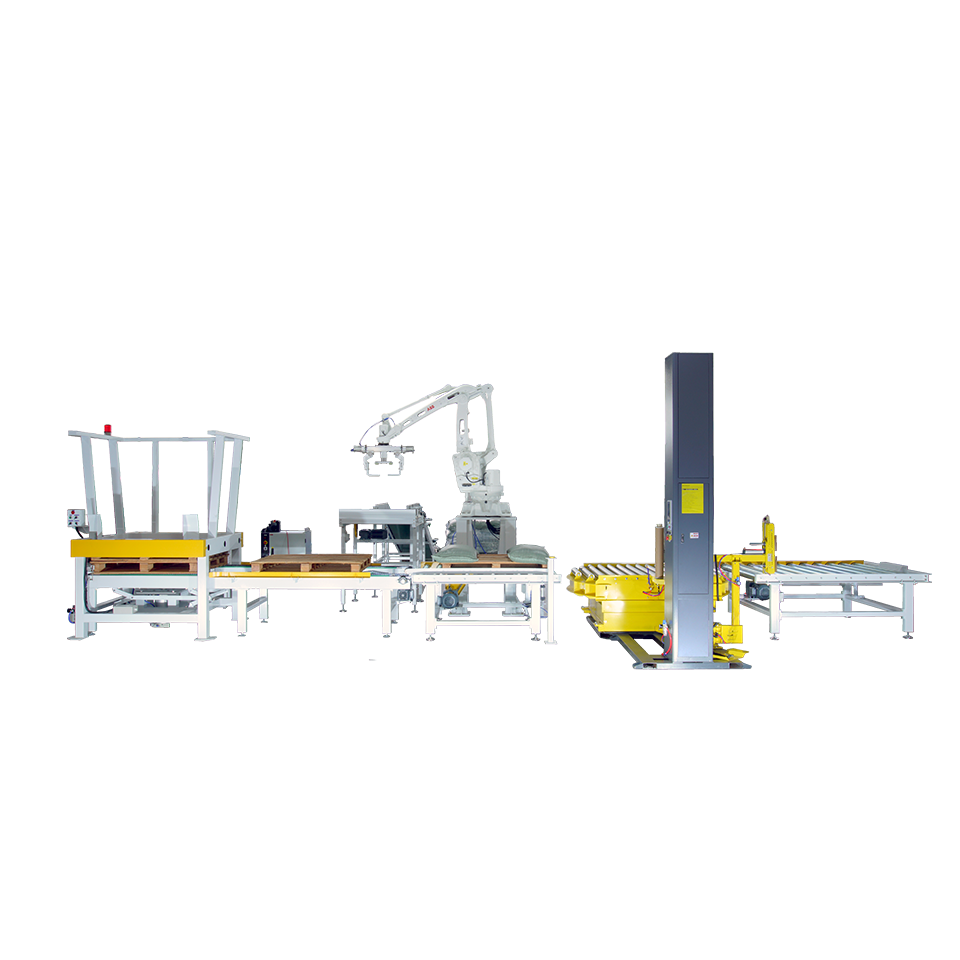

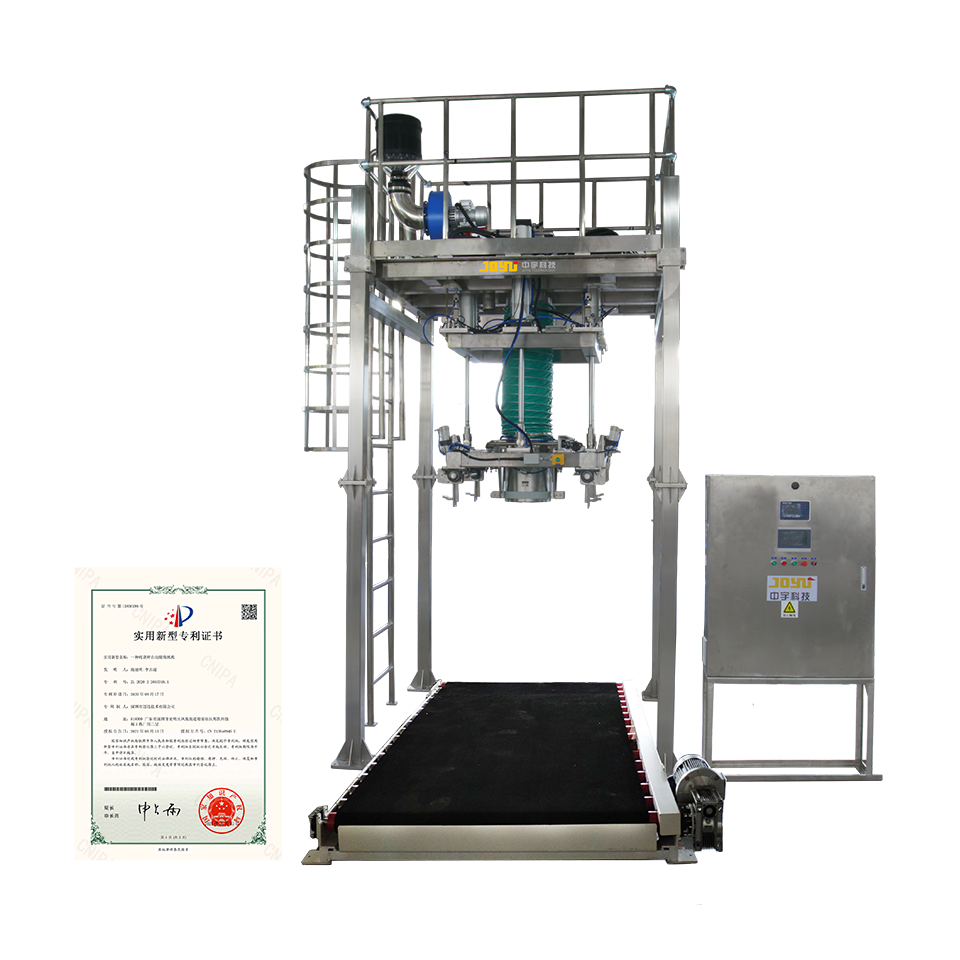

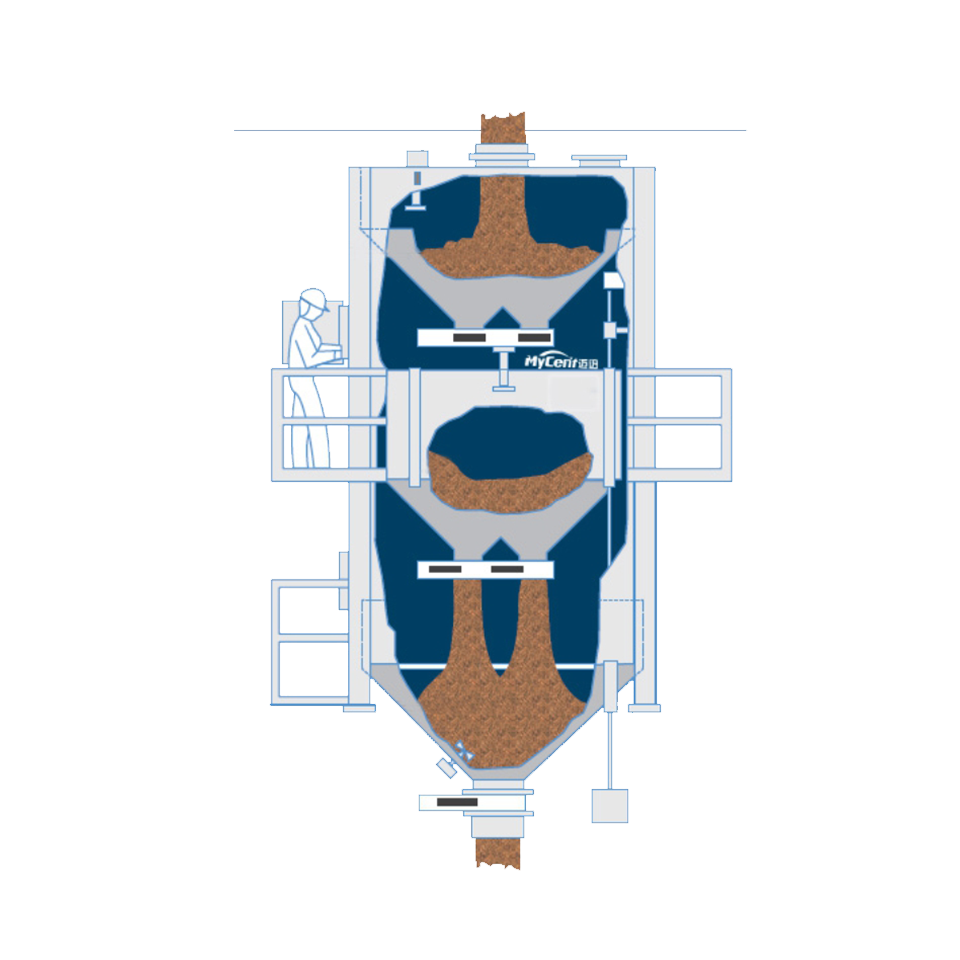

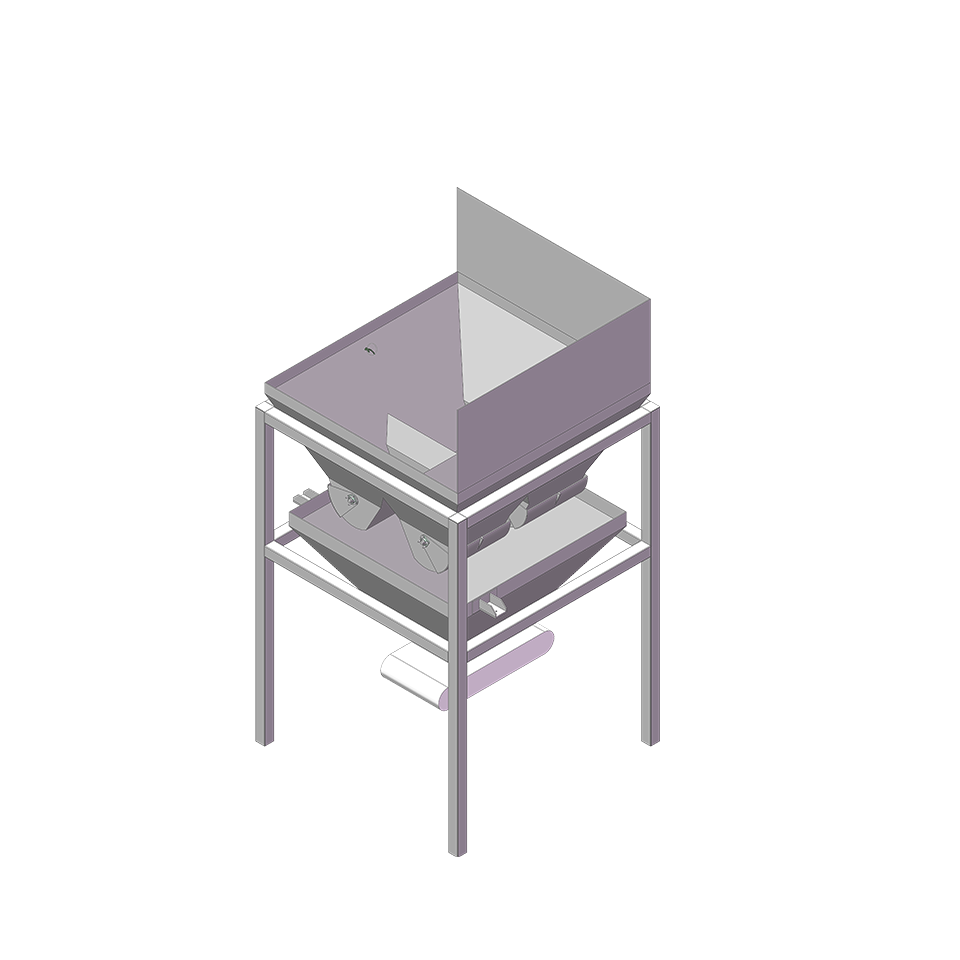

The systems and projects from feeding, conveying, batching, mixing (extrusion), granulation to automatic packaging and stacking are built according to the specific requirements of each application, ensuring that JOYU provides comprehensive process improvement, upstream and downstream, enterprise wide, and enters the supply chain.